Welcome to KEW International – Your Global Partner in Engineering Excellence

KEW International, a proud subsidiary of Krishna Engineering Works, is your trusted global source for world-class machinery and turnkey solutions across Flexible Packaging, Converting, Textile Processing, Printing, Paper, and Tyre-Cord industries.

With over 25 years of engineering excellence and a legacy of award-winning innovation, KEW International is dedicated to empowering industries worldwide with advanced, export-quality machinery. Our state-of-the-art equipment is designed to optimize production, minimize downtime, and deliver unmatched performance across a wide range of applications—from raw material handling to finished product processing.

Headquartered in Ahmedabad, India, and backed by a strong manufacturing base, KEW International is built on a foundation of technology leadership, quality craftsmanship, and customer-first service. With 105+ successful installations in over 30 countries, including the USA, Canada, Mexico, Brazil, Russia, UAE, South Africa, and beyond, we are strategically focused on expanding our global footprint.

Whether you’re looking for precision-engineered Slitting Rewinding Machines, Rotogravure Printing Presses, Web Guiding Systems, Coating & Laminating Machines, or Textile & Tyre-Cord Solutions, KEW International offers everything under one roof—manufactured with strict quality control and supported by prompt global service.

We invite international partners, distributors, and end-users to connect with us for customized solutions that match your industry’s evolving needs. At KEW International, we don’t just sell machines—we deliver engineering confidence, international trust, and long-term partnerships.

Let’s build your future of manufacturing excellence—globally.

New Machines Kew International

Introducing our latest innovations — engineered for performance, precision, and reliability.

Slitter Rewinder Machine

Our Slitter Rewinder Machines are engineered for unparalleled precision across all material types and custom industrial applications, offering high-quality, high-speed, and versatile solutions trusted globally.

Winding Rewinding Machine

Slitter Rewinder Machines process diverse materials for custom applications, providing precise, high-speed, and reliable web handling.

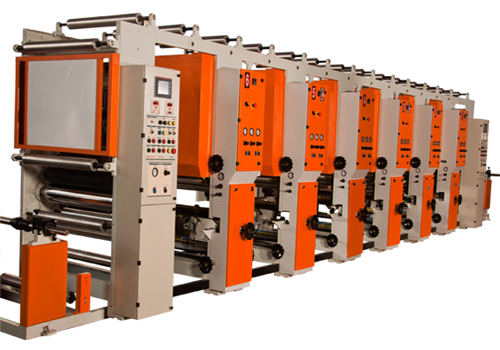

Rotogravure Printing Machine

Rotogravure Printing Machines enable high-quality, consistent printing on flexible substrates for various applications.

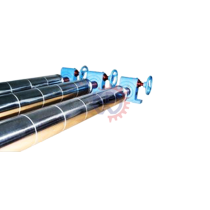

Rubber Roller

Rubber Rollers are essential components for various machines, providing consistent grip and pressure for material processing.

BOPP Tape Slitting Machine

BOPP Tape Slitting Machines precisely cut large rolls of BOPP tape into narrower, usable widths for various packaging needs.

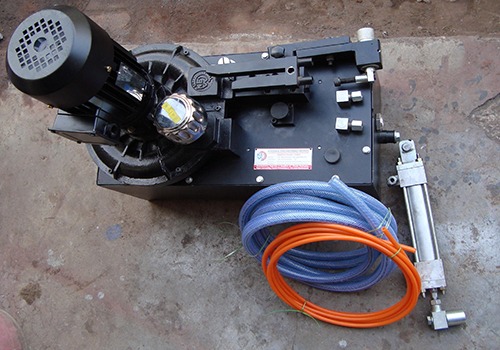

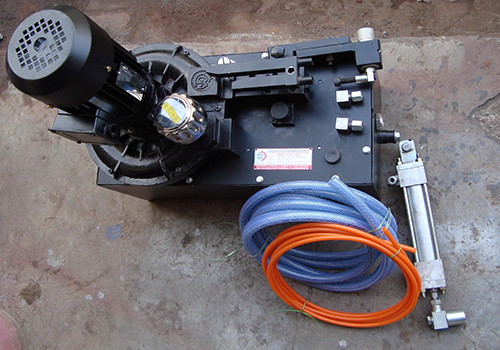

Web Guiding System

Web Guiding Systems automatically align flexible materials of any width, load, or speed for accurate processing in printing, packaging, and converting.

Our Popular Machinery & Equipment Offerings

As a leading manufacturer, exporter, and supplier, KewInternational specializes in heavy-duty and high-speed machines designed for superior performance across various industries.

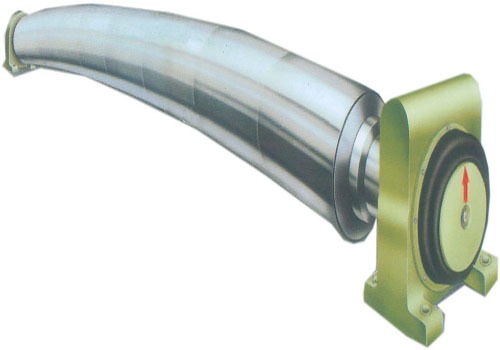

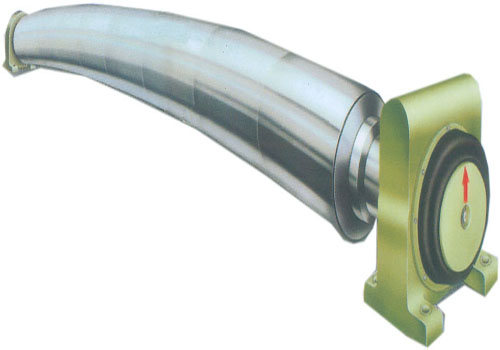

Metal Bow Roll

- Durable, precision-engineered build – Includes bowed shafts, sealed bearings, abrasion-resistant sleeve, and metal segments.

- Flexible mounting options – Supplied with foot or wall-mounted brackets and optional gear set.

- Wide industrial compatibility – Printing, Textile, Packaging, Paper.

Banana Roll (Expander Roller)

- Wrinkle removing solution – Effectively eliminates wrinkles and separates slit webs in various web handling applications.

- Wall or foot mounting – Supplied with versatile mounting brackets and optional gear sets for easy installation.

- Heavy-duty construction – Built with bowed shafts, sealed ball bearings, abrasion-resistant sleeves, and durable metal segments.

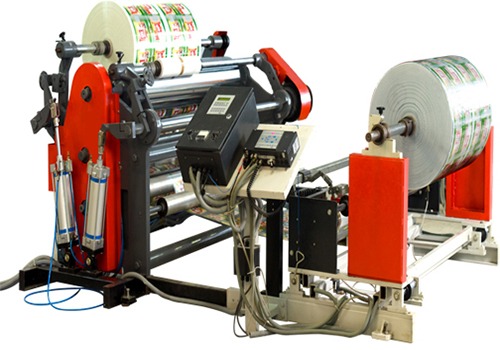

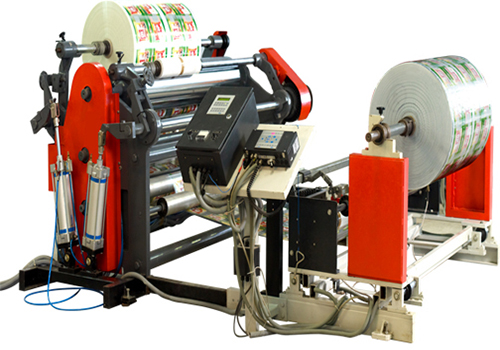

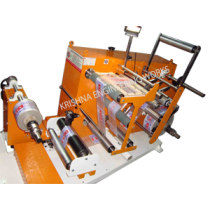

Rotogravure Films Printing Machine

- Proven global performance – Over 105 installations across India and 25+ countries worldwide.

- Multi-material processing – Efficiently prints on Polyester, BOPP, LD, PVC, Paper, Foil, Film, and more.

- Award-winning quality – Recognized with 3 National and 2 International Awards for excellence in manufacturing.

BOPP Tape Slitting Machine

- 300 mm working width – Suitable for slitting adhesive tapes from 12 mm and above.

- Robust construction – Includes MS side walls, DC/AC motor with drive, unwinder, rewinder, control panel, and auto stop counter meter.

- Multi-tape compatibility – Ideal for BOPP tapes, masking tape, tissue/fabric tapes, and protection tapes.

Rotogravure Printing Machine

- 25+ years expertise – Trusted manufacturer, exporter, and supplier from Ahmedabad, India.

- Multi-material capability – Suitable for Polyester, BOPP, LD, PVC, Paper, Aluminum Foil, Film, etc.

- Global presence – 105+ installations across India, Africa, Asia, South America, and North America.

BOPP Tape Coating Machine

- 1000 mm working width – Designed for high-efficiency BOPP tape coating operations.

- Fully equipped system – Includes two web aligner units, heaters, blower, motor with panel, and complete accessories.

- Turnkey solution – Delivered complete as per technical specification annexure.

Inspection Winding Rewinding Machine

- Optional tension control – Equipped with mechanical 1.5 / 2.5 Kg brake or magnetic powder brake with tension controller.

- Inkjet printing ready – Provision to integrate inkjet printing system with hot air ink drying.

- Correction-oriented design – Specially designed model for web inspection and error correction tasks.

Inspection Doctoring Slitting Machine

- Cantilever design – Ensures easy reel loading/unloading with balanced body and compact structure.

- Advanced web handling – Includes movable unwind stage with hydraulic edge guiding system and optional magnetic powder brake.

- Coding-ready system – Suitable for inkjet printing with hot air drying; ideal substitute for online coding/batching operations.

Doctoring Slitting Rewinding Machine

- Cantilever design – Balanced structure for easy loading/unloading of parent and rewound reels.

- Web alignment system – Movable unwind stage with hydraulic web aligner and optional magnetic powder brake.

- Inspection & coding ready – Ideal for doctoring, reel correction, and inkjet printing with hot air drying.

Doctoring Rewinding Machine

- Cantilever design – Enables easy loading/unloading with balanced body and compact structure.

- Advanced control system – Features variable speed drive, double drive, and optional magnetic powder brake with tension control.

- Ideal for reel correction – Designed for doctoring, inspection, and supports inkjet printing with hot air drying.

Need a Quick Quote or Technical Consultation?

Our international sales team is ready to assist you.

📞 Contact Us Now – +91-8460728298