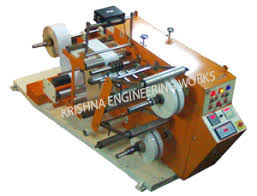

Inspection Machines – Global Web & Surface Quality Control by KEW International

KEW International is a manufacturer and exporter of high-speed Inspection Machines for flexible packaging, printing, textile, and paper industries in the USA, Canada, Brazil, Russia, France, South Africa, and Mexico, which provide reliable defect detection and assure 100% quality at high speeds. International manufacturers trust KEW Inspection Machine to improve operations while either reducing waste, improving productivity, and building superior brands.

Features of KEW International Inspection Machines

- High-definition camera systems for accurate defect recognition

- Variable working widths for different substrates

- Compatible with slitter rewinder machines, rotogravure printing machines, stenter machines, and flexo printing machines

- Durable design for uninterrupted use in industrial environments

- Real-time inspection with software platform

- International service and parts support

Use cases Kew’s Inspection Machines

– Identify print errors in rotogravure and flexographic printing

– Find surface defects on banana rollers, web aligners, and cutting machines for BOPP

– Verify product quality on core cutter machines and rewinder machines

– Monitor continuous web flow for Hydro Pneumo Web Aligner Systems

Technical Specifications of our Inspection Machines

- Web Width: 300 mm – 3000 mm (customizable)

- Speed: Up to 600 m/min

- Camera Resolution: 4K UHD

- Types of Defects Detected: Printing faults, color inconsistencies, misalignments, coating problems

- Integration: Compatible with KEW slitter rewinders & printing machines

Why Choose KEW International for Inspection Machines?

– More than 40 years in the manufacturing sector

– Exporting worldwide, and a base of international customers

– Complete after-sales support, and spare parts are readily available

– Capable of in-house Research & Development for continuous innovation

Watch Our Inspection Machine Running

Video of Our Inspection Machine

Contact KEW International Regarding Inspection Machines

If you have inquiries specifically related to Inspection Machines and the spare parts:

☎️ Phone: +91-8460728298

📧 Email: info@kewindia.com

Frequently Asked Questions about Inspection Machines

Q1: What do you mean by an Inspection Machine?

An inspection machine is equipment utilized to find defects or problems in paper, film, textiles, or printed substrates during production to ensure quality.

Q2: What are the four types of quality inspections?

Pre-production, in-process, final random, and container loading inspection.

Q3: What equipment is used for inspection?

Inspection can be conducted using vision inspection systems, camera based web inspection systems, and automated defect detection systems.

Q4: How many inspections are there?

There are four different types of inspections. Visual, dimensional, functional, and automated inspections.

Q5: What is the purpose for an inspection?

To verify that products are meeting quality standards, reduce defects, and therefore improve customer satisfaction.

Q6: Is inspection QA or QC?

Inspection is a quality control (QC) activity to check conformance to specifications.

Q7: What is a machine inspection?

Machine inspection means routinely checking machinery to see if it is durable (wearing out), defective, or misaligned, to help ensure it is operating in an optimal state.